CLAAS has raised the bar for forage harvesting with the V-FLEX chopping cylinder, now optionally available for pre-ordered JAGUAR 900 series forage harvesters. This innovation sets new productivity, flexibility, and efficiency standards, enabling farmers and contractors to achieve exceptional results.

This new development continues CLAAS’s legacy of customer-focused innovation, backed by over 50 years of forage harvesting expertise. Farmers and contractors using the V-FLEX-equipped JAGUAR can expect a season of reliable, efficient harvesting, with advanced precision and ease of use.

Additionally, CLAAS has streamlined sharpening and shear bar adjustment processes, completing them in just one minute, minimizing downtime, and boosting operational efficiency.

Product Business Manager – Green Harvest, Luke Wheeler says, “Reduced setup time, lower fuel consumption per tonne, and a significant boost in throughput, alongside faster sharpening and shearbar settings ensures the avoidance of any harvesting delays”.

The 2025 JAGUAR 900 series enhancements include:

- New V-FLEX chopping cylinder for JAGUAR 900 / JAGUAR 900 TERRA TRAC as optional alternative to the V-MAX for even greater versatility.

- V-FLEX knives: 23 mm anti-wear coating for exceptional service life and new geometry with 10 degree cutting angle for precise cut in all crops. Significant reduction in noise levels and improved chopping quality.

- Optimised process management for knife sharpening and shear bar adjustment – now available as a combined option for even fewer downtimes.

- Factory-fitted speed differential of up to 40 per cent for MCC CLASSIC and MCC MAX corncrackers and new MCC CLASSIC with fine sawtooth profile for use in small-seeded crops such as sorghum.

- Larger maintenance compartment for faster, more convenient changeover of corncracker module.

- PICK UP: new intake auger with four paddles ensures uniform crop flow with reduced torque peaks and higher throughput

- New Carraro rear axle with four-wheel drive engagement under load and option of extending track by 460 or 620 mm.

V-FLEX Chopping Cylinder and Knives

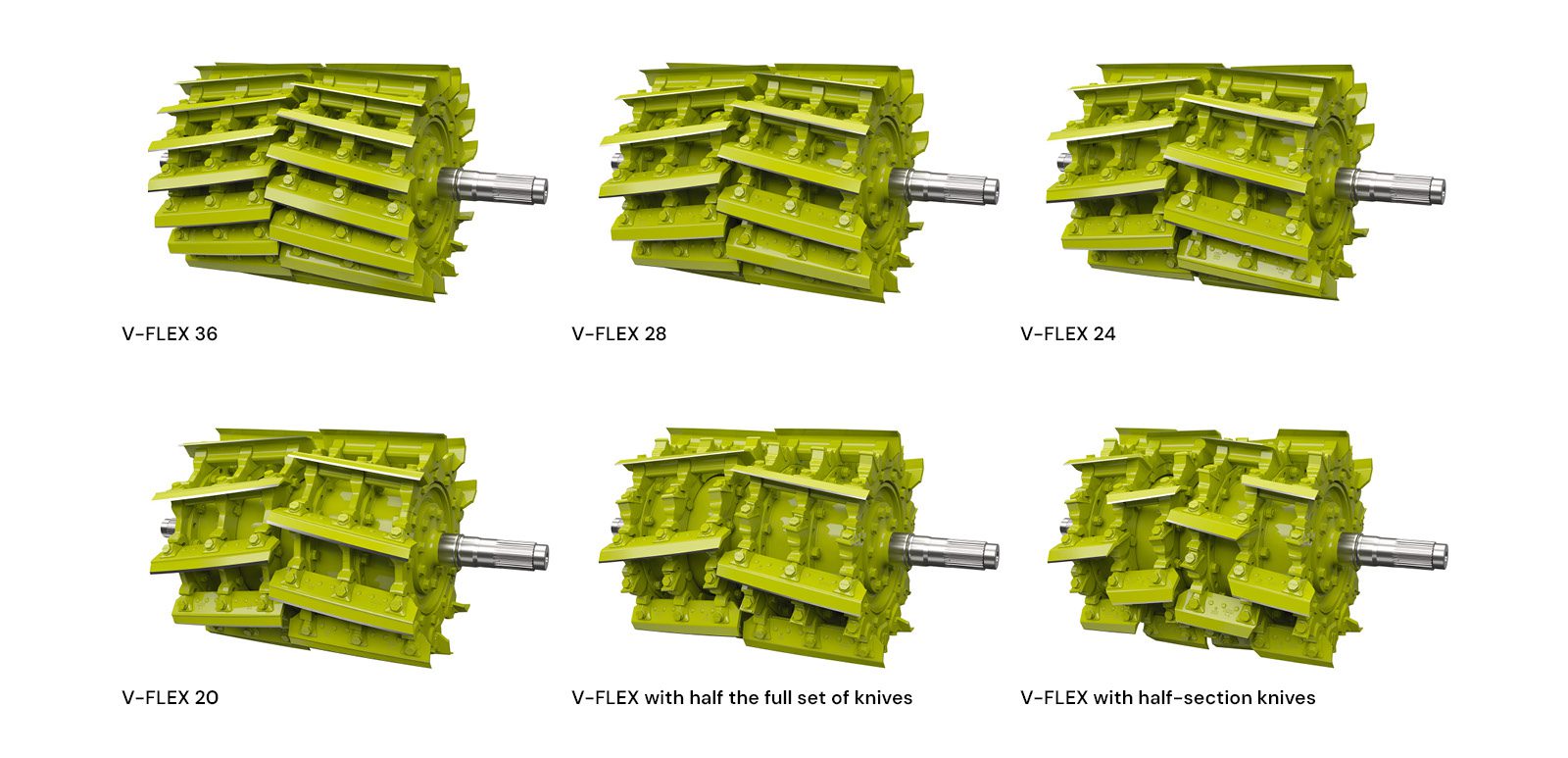

The new V-FLEX chopping cylinder offers unparalleled versatility for all applications and chop lengths with full and half sets of knives, as well as half-knives.

The V-FLEX cylinder brings remarkable versatility with a unique design supporting multiple knife configurations, allowing operators to effortlessly adjust chop lengths and adapt to varied crop conditions, enhancing performance and precision. The triple-bolted knives, equipped with a durable 23mm anti-wear coating and angled at 10 degrees to the shear bar, offer superior stability, reduced wear, and greater operational intervals. With its optimised V-angle and new V-FLEX knives, the cylinder delivers higher throughput, lower noise levels, and smoother operation, ensuring a more consistent crop flow, especially at chop lengths over 12mm.

The V-FLEX cylinder is available in four configurations—20, 24, 28, and 36 knives—offering adaptable settings such as full-knife, half-knife, and one-third knife modes to extend chop lengths.

The V-FLEX 36 can operate in multiple modes: 36 knives for full capacity, 18 knives in half mode, or a third mode with 12 knives. A new variant, with 36 half-knives, doubles the length of cut for optimal crop flow and chopping quality. These configurations provide a versatile cutting range from 3.5 mm up to 53 mm, supporting maize harvesting at lengths up to 30mm in combination with MCC CLASSIC, MCC MAX, and MCC SHREDLAGE corn crackers. This versatility ensures a smooth material flow, precise cuts, and reduced processing costs, contributing to superior feed quality.

The newly developed V-FLEX knives feature several outstanding improvements in terms of wear protection, throughput and smooth running.

PICK UP 300: optimised crop flow and fewer losses

The new PICK UP 300 for JAGUAR 800, 900 and 900 TERRA TRAC is characterized by less soiling in the intake and more even, slightly increased throughput.

When it comes to the PICK UP 300, the shape of the auger has been redesigned with four offset central feed paddles. This ensures even more uniform crop flow, which in turn has a positive effect on throughput. The flat or toothed paddle extensions are easy to replace or changeout in challenging conditions.

The extended dust screen now covers the entire working width of the PICK UP. This reduces material buildup on the top of the feeder housing, cutting cylinder and front windscreen. It effectively captures all crop types, avoiding harvest losses. The wide-mesh screen still provides a clear view of crop flow from the cab.

“The new one-piece dust screen can easily be swung open for maintenance work”, Luke says.

CLAAS Corn cracker: more speed difference and more space

The MCC CLASSIC and MCC MAX now work with a speed difference of up to 40 percent, and the MCC CLASSIC is also available with fine gearing. Thanks to the larger maintenance space, installation and removal of the corn cracker module is quicker and less stressful.

For years the CLAAS MULTI CROP CRACKER concept (MCC) comprising the MCC CLASSIC, MCC MAX and MCC SHREDLAGE has offered the widest choice of corn cracker options for highly efficient processing of kernels, leaves and stalks – from short-cut to long-cut and SHREDLAGE.

For more intensive kernel processing, the differential speed has been increased from 30 to 40 percent in the MCC CLASSIC with a sawtooth profile, and the MCC MAX, with unique ring segments and cutting and shearing effects. Furthermore, the MCC CLASSIC is optionally available with a new 190 sawtooth profile-roller designed for particularly small kernels like sorghum.

The maintenance compartment on all JAGUAR 900 series machines has been enlarged to provide additional space for the fitting and removal of the corn cracker.

Luke said, “Having the extra room in the side opening makes it easier to fit the corn cracker when changing from Grass to Maize”.

Carraro rear axle

The 2025 JAGUAR will be fitted with the new Carraro rear axle. Sporting a load capacity of 9 tonnes and 10-hole rims in the POWER TRAC variant, the Carraro axle enables four-wheel drive to be engaged under load. Furthermore, wheel spacers of 460mm for the standard axle and 620mm for the POWER TRAC four-wheel drive axle are available to widen the track.

With more than 45,000 units manufactured over the past 50 years, JAGUAR has earned a hard-won reputation for productivity, efficiency and reliability. CLAAS’s continual focus on improving the machine and its performance in the field will ensure it remains rated as the world’s number one forage harvester. The CLAAS JAGUAR offers cost-effective chopping to the highest professional standards under all field conditions.

JAGUAR 900 Series

With more than 46,000 machines produced since 1973, the CLAAS JAGUAR 900 is the world’s number one forage harvester for sale. With up to 925hp via a MAN V12 engine, throughput of up to 380t/ha, and fuel consumption as low as 0.41L/t1, JAGUAR is the maize harvester on everyone’s wishlist.